Installation and Maintenance – Cast Glider L-Hooks for B Boost Glide

Proper installation and maintenance of cast L-hooks are essential for achieving consistent, reliable performance in B/G competition. Even the best-designed and manufactured hooks can fail to deliver optimal results if not properly installed or maintained, potentially compromising flight success and safety.

Installation procedures must ensure that hooks are correctly positioned, securely attached, and properly interfaced with retention mechanisms to provide reliable performance throughout the flight profile. This process requires attention to detail and adherence to established procedures to avoid common installation errors.

Maintenance practices extend component life, ensure continued reliability, and identify potential issues before they affect flight performance. Regular, systematic maintenance is particularly important for L-hooks that experience repeated loading cycles and environmental exposure.

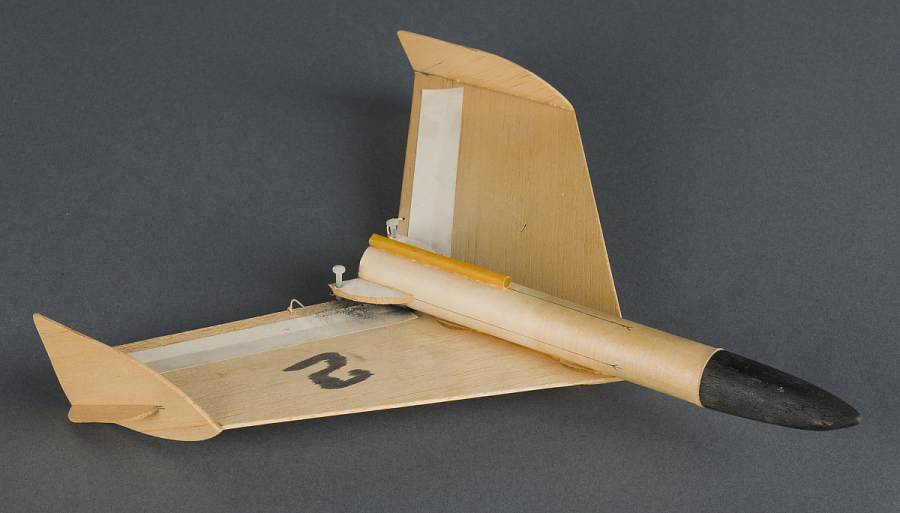

Proper Placement and Mounting on the Glider

Correct L-hook placement and mounting are fundamental to achieving reliable boost-to-glide transition and optimal flight performance. Improper installation can compromise both structural integrity and aerodynamic performance, potentially leading to mission failure or safety issues.

Location Selection Criteria

Structural considerations determine optimal hook placement locations that can accommodate expected loads without creating stress concentrations or failure points. Hooks should be mounted on structurally reinforced areas of the glider with adequate load paths to primary structural elements.

Aerodynamic factors affect hook placement to minimize drag and flow interference while maintaining functional requirements. Hooks should be positioned to avoid high-drag regions and potential flow separation areas that could affect overall vehicle performance.

Accessibility requirements ensure that hooks can be easily installed, inspected, and maintained without requiring disassembly of other glider components. This consideration is particularly important for competitors who fly frequently and need rapid turnaround between flights.

Mark optimal hook positions on gliders with permanent reference marks to ensure consistent installation and facilitate quick setup during competition. These marks should be clearly visible and resistant to wear from handling.

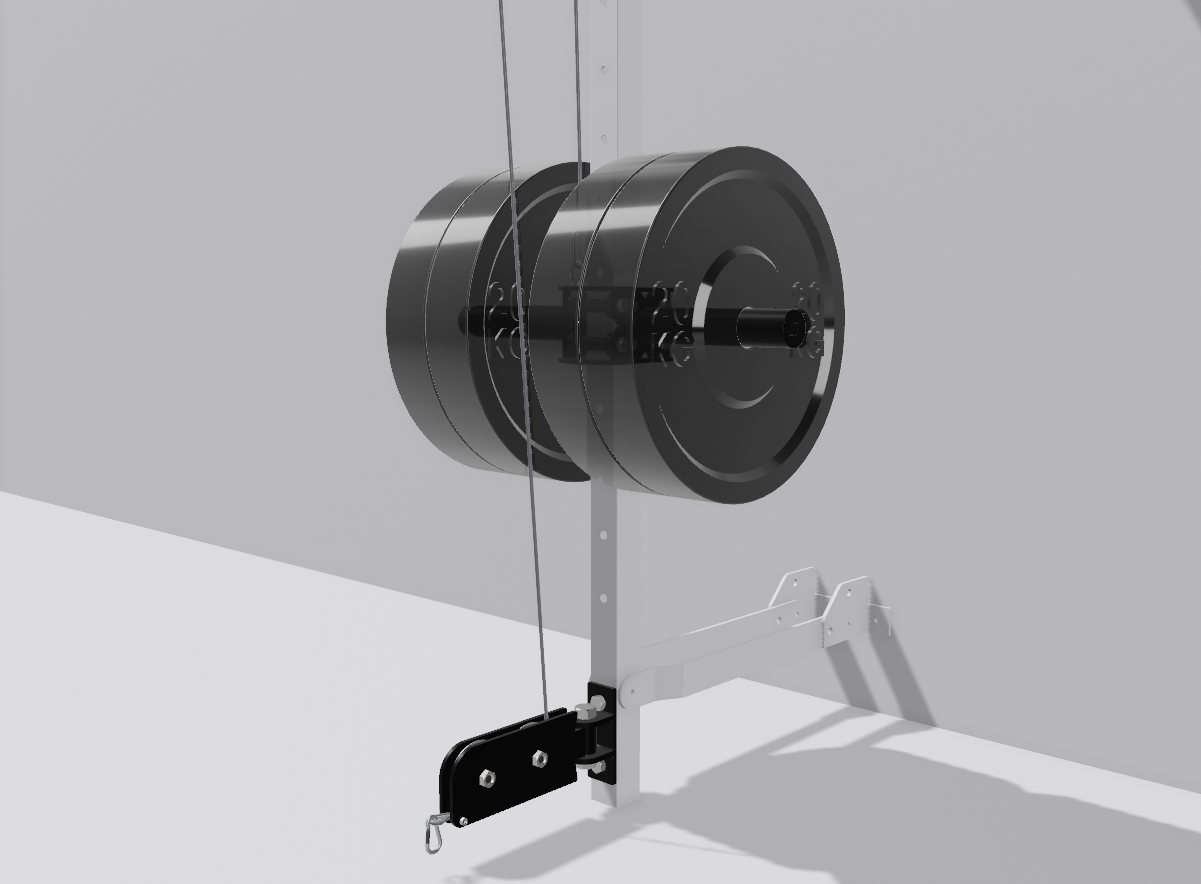

Mounting Hardware and Techniques

Mounting hardware selection affects both installation reliability and structural integrity, requiring components that can withstand expected loads while providing secure attachment. Hardware should be compatible with both hook materials and glider construction.

Threaded fasteners offer excellent adjustability and removal characteristics but require proper torque control and thread locking compounds to prevent loosening during flight. These fasteners should be regularly inspected and retightened as needed.

Adhesive bonding can provide excellent load distribution and eliminate stress concentrations associated with mechanical fasteners, but requires careful surface preparation and curing procedures to achieve optimal strength. This method is particularly effective for lightweight hooks.

Alignment and Orientation

Hook alignment affects both retention reliability and release characteristics, requiring precise positioning to ensure proper interface with retention pins and smooth separation behavior. Misalignment can cause binding, incomplete release, or premature separation.

Orientation control ensures that hooks are positioned correctly relative to glider flight attitude and loading directions. Proper orientation minimizes off-axis loads and ensures that primary load paths align with hook strength characteristics.

Symmetry considerations become important for gliders with multiple hooks or symmetric designs, requiring matched positioning and orientation to maintain balanced loading and flight characteristics. Asymmetric hook placement can create unwanted rolling moments.

Inspecting for Stress and Fatigue

Regular inspection for stress and fatigue damage is essential for maintaining L-hook reliability and preventing unexpected failures during flight. These inspections should be systematic and thorough, focusing on areas most susceptible to damage from repeated loading and environmental exposure.

Visual Inspection Techniques

Surface condition assessment identifies visible signs of wear, corrosion, or mechanical damage that could affect hook performance or structural integrity. This assessment should include examination of all contact surfaces, mounting points, and areas of stress concentration.

Crack detection using visual inspection can identify surface-breaking cracks that may propagate under continued loading. Magnification tools and proper lighting can improve crack detection capability, particularly for fine cracks in highly stressed areas.

Dimensional verification ensures that hooks maintain required clearances and alignment with retention mechanisms. Changes in critical dimensions can affect retention force or release reliability, requiring corrective action before flight.

- Examine all hook surfaces for scratches, dents, or other damage

- Check hook throat dimensions for wear or deformation

- Inspect mounting points for cracks or loosening

- Verify retention pin contact surfaces for excessive wear

- Check for signs of corrosion or environmental damage

- Assess overall hook alignment and orientation

Non-Destructive Testing Methods

Dye penetrant inspection reveals surface-breaking cracks and other discontinuities that might not be visible to the naked eye. This technique is particularly effective for identifying small cracks that could grow under continued loading.

Magnetic particle inspection can detect subsurface cracks and other discontinuities in ferromagnetic materials, providing information about internal damage that could affect structural integrity. This method requires specialized equipment and trained operators.

Ultrasonic testing can identify internal defects such as porosity or inclusions that could compromise component strength. This testing is particularly valuable for critical applications where internal quality is important.

Fatigue Damage Recognition

Fatigue crack initiation typically occurs at stress concentration points such as sharp corners, holes, or surface defects. These locations should receive special attention during inspection, particularly for hooks with extended service history.

Beach mark analysis can provide information about crack growth history and loading conditions that contributed to failure. This analysis requires careful examination and may provide insights for improving future designs or maintenance procedures.

Load history tracking enables correlation between service conditions and observed damage, helping to identify situations that may accelerate fatigue or wear. This tracking is particularly valuable for competitors who fly in varying conditions.

Maintenance Procedures and Schedules

Systematic maintenance procedures ensure that L-hooks continue to provide reliable performance throughout their service life while identifying potential issues before they affect flight operations. These procedures should be tailored to specific usage patterns and environmental conditions.

Cleaning and Surface Treatment

Regular cleaning removes contaminants that could affect hook performance or accelerate wear and corrosion. Cleaning procedures should be compatible with hook materials and coatings to avoid damage during the process.

Surface treatment maintenance preserves protective coatings and finishes that prevent corrosion and reduce friction. These treatments should be reapplied according to manufacturer recommendations or when visual inspection indicates degradation.

Lubrication of moving parts such as retention pins ensures smooth operation and prevents galling or seizing that could affect release reliability. Lubricants should be compatible with hook materials and operational environments.

| Maintenance Activity | Frequency | Criticality |

|---|---|---|

| Visual inspection | Before each flight | High |

| Dimensional verification | Every 10 flights | Medium |

| Surface cleaning | After each flight | Medium |

| Lubrication | Every 5 flights | Medium |

| Non-destructive testing | Annually or every 50 flights | Low |

Component Replacement Criteria

Wear limits define maximum acceptable dimensional changes or surface degradation before component replacement is required. These limits should be established based on functional requirements and safety considerations.

Damage thresholds specify conditions that require immediate component replacement regardless of service history. These thresholds should be clearly defined and easily identifiable during inspection.

Service life limits prevent continued use of components beyond their design life, regardless of apparent condition. These limits should be based on testing data, analysis, or conservative estimates of fatigue life.

Record Keeping and Tracking

Service history documentation enables tracking of component usage and identification of potential issues before they affect performance. This documentation should include flight counts, loading conditions, and any maintenance or repairs performed.

Inspection records provide objective evidence of component condition and enable trend analysis to identify developing problems. These records should include photographs or detailed descriptions of any anomalies observed.

Maintenance scheduling ensures that required activities are performed on time and that components do not exceed established service limits. This scheduling should be integrated with overall glider maintenance procedures for consistency.

Troubleshooting Common Issues

Understanding common L-hook problems and their solutions enables quick diagnosis and correction of issues that could affect flight performance or reliability. This knowledge is particularly valuable during competition when rapid problem resolution is essential.

Retention and Release Problems

Inadequate retention force typically results from hook wear, improper alignment, or insufficient hook throat engagement. Solutions include hook replacement, alignment adjustment, or verification of retention pin dimensions.

Difficult release often stems from surface roughness, corrosion, or binding between hook and retention pin. Remedies include surface polishing, cleaning and lubrication, or verification of proper hook and pin dimensions.

Premature release can result from hook damage, excessive retention pin wear, or improper installation. Correction requires inspection and replacement of damaged components, verification of proper installation, and adjustment of retention mechanisms.

Structural Integrity Concerns

Cracking or fracture typically indicates excessive loading, material fatigue, or stress concentration issues. Resolution requires identification of root cause, component replacement, and design or usage modifications to prevent recurrence.

Deformation or bending suggests overload conditions or inadequate hook strength for applied loads. Solutions include hook redesign, loading condition modification, or selection of higher strength materials.

Mounting point failure indicates inadequate attachment strength or improper load transfer. Correction requires reinforcement of mounting points, improved attachment methods, or redistribution of loads to stronger structural elements.

Environmental and Corrosion Issues

Corrosion damage affects hook strength and surface condition, requiring cleaning, treatment, or replacement depending on severity. Prevention includes proper storage, protective coatings, and compatible material selection.

Contamination from dirt, salt, or other environmental factors can affect hook performance and accelerate wear. Regular cleaning and proper storage can prevent most contamination-related issues.

Thermal effects from motor operation or environmental exposure can cause dimensional changes or material degradation. Design modifications or material selection changes may be necessary to address thermal issues.

Never fly with L-hooks that show signs of cracking, significant wear, or other structural damage. Replace questionable components before flight to ensure mission success and personnel safety.

Storage and Transportation

Proper storage and transportation practices preserve L-hook condition and prevent damage that could affect flight performance. These practices are particularly important for competitors who travel to events or store equipment for extended periods.

Storage Environment Requirements

Temperature control prevents thermal cycling that could cause dimensional changes or material degradation. Hooks should be stored in stable temperature environments away from direct sunlight or heat sources.

Humidity control prevents corrosion and moisture absorption that could affect hook materials or coatings. Desiccant storage or climate-controlled environments may be necessary for sensitive materials or extended storage periods.

Contamination prevention maintains hook surface condition and prevents damage from handling or environmental exposure. Proper storage containers and handling procedures protect hooks between flights.

Transportation Protection

Impact protection prevents damage from handling or transportation vibration that could affect hook geometry or surface condition. Cushioning materials and secure mounting protect hooks during transport.

Separation prevention maintains hook organization and prevents damage from contact between components. Individual packaging or compartmentalized storage prevents hooks from contacting each other or other equipment.

Identification and tracking ensure that hooks can be quickly located and their service history accessed when needed. Labeling systems and inventory control prevent loss or misuse of components.

Use dedicated storage containers with individual compartments for each hook to prevent damage and maintain organization. Include service history cards or tags with each hook for quick reference.

Post Comment