Model Optimization and Flight Trimming – Competition & Contest Flying

Model optimization and flight trimming represent the intersection of engineering science and practical artistry that distinguishes competitive rocketeers from casual hobbyists. The most successful competitors understand that marginal gains in performance often determine the difference between winning and losing, requiring systematic approaches to vehicle refinement and precise adjustment of flight characteristics.

Optimization encompasses all aspects of vehicle design and construction that affect performance, from fundamental aerodynamic shaping to minute details of surface finish and component integration. This comprehensive approach requires both theoretical understanding and empirical validation through systematic testing and measurement.

Flight trimming focuses specifically on adjusting vehicle characteristics to achieve optimal performance under specific flight conditions and mission requirements. This process requires careful observation, precise measurement, and iterative refinement to achieve peak performance levels.

Techniques for Reducing Weight and Drag

Weight and drag reduction form the foundation of performance optimization for competitive model rockets, as both factors directly affect flight performance across all event categories. Systematic application of reduction techniques can provide measurable advantages that compound across the entire flight profile.

Structural Weight Optimization

Material selection significantly affects structural weight while maintaining required strength and stiffness characteristics. Advanced materials such as carbon fiber, advanced composites, and high-strength alloys can provide substantial weight savings compared to traditional materials.

Structural optimization techniques including topology optimization, variable wall thickness, and selective material placement enable maximum strength with minimum weight. These techniques require careful analysis and testing to ensure structural adequacy.

Joinery and connection optimization reduces weight while maintaining load transfer efficiency and structural integrity. Precision-fitted joints, optimized fastener selection, and strategic placement of connection points can eliminate unnecessary mass.

Focus weight reduction efforts on components that contribute significantly to total vehicle mass while having minimal impact on structural requirements. Small percentage reductions in heavy components often provide greater absolute benefits than larger percentage reductions in lightweight components.

Aerodynamic Drag Minimization

Form drag reduction through optimized vehicle shaping represents the most significant opportunity for performance improvement in most rocket designs. Streamlined nose cones, boat-tail transitions, and smooth body contours can provide substantial drag reduction.

Skin friction drag reduction through surface finishing and treatment affects vehicle performance throughout the entire flight envelope. Proper sanding, filling, and painting techniques can reduce drag by 5-10% compared to rough or unfinished surfaces.

Interference drag reduction through careful component integration and fairing design eliminates flow separation and pressure drag caused by abrupt changes in vehicle cross-section. This reduction requires attention to detail in component placement and transition design.

Component and System Optimization

Recovery system optimization balances deployment reliability with weight and drag considerations to achieve optimal performance for specific events. Parachute size, streamer dimensions, and deployment timing all affect total flight performance.

Motor system optimization includes selection of motors with appropriate thrust curves, optimization of motor retention and ejection charge systems, and integration with vehicle structure to minimize weight and drag penalties.

Payload and instrumentation optimization ensures that required components contribute to mission success while minimizing negative impact on flight performance. This optimization may involve miniaturization, integration, or elimination of non-essential components.

Practice Flights: Trimming for Peak Performance

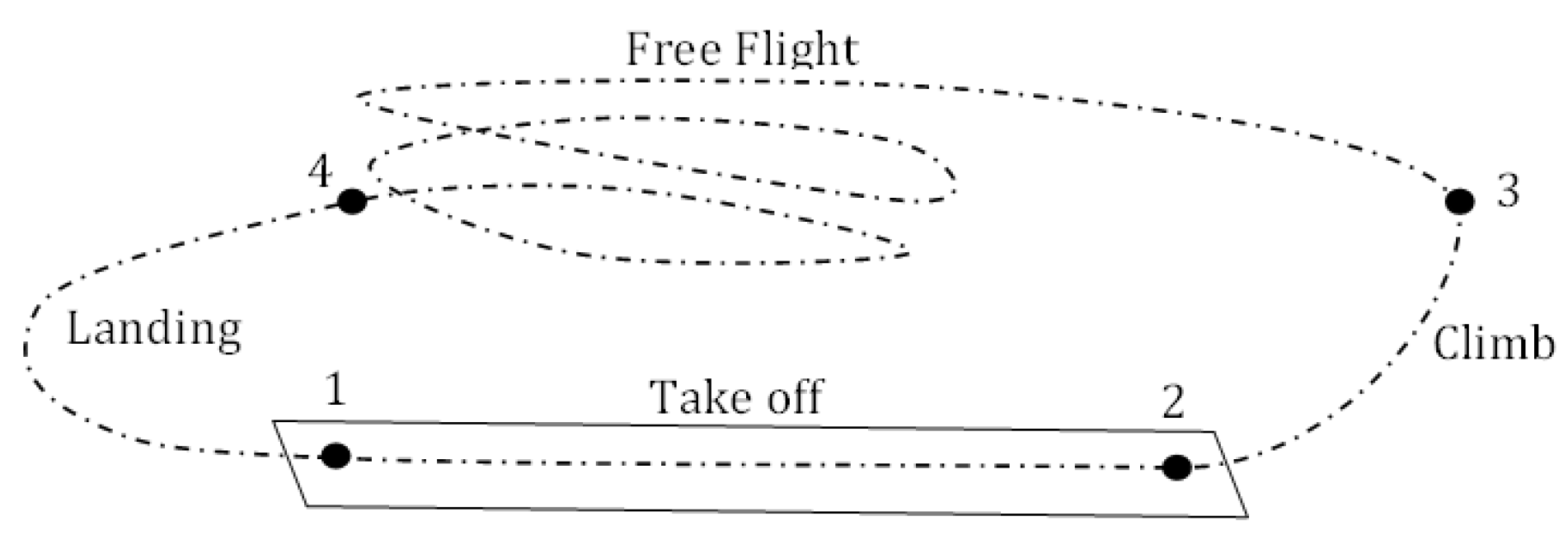

Practice flights form the empirical foundation of flight trimming, providing objective data about vehicle performance and behavior that cannot be obtained through analysis alone. Systematic practice flight programs enable precise adjustment of vehicle characteristics to achieve peak performance under specific conditions.

Data Collection and Analysis

Flight parameter measurement including altitude, velocity, acceleration, and flight time provides objective data for performance evaluation and optimization. Modern electronic altimeters and flight computers enable precise measurement of these parameters.

Observational data collection including visual tracking, video recording, and photographic documentation provides qualitative information about flight behavior and vehicle performance. This information complements quantitative measurements and can reveal issues not apparent from numerical data alone.

Statistical analysis of multiple flight data enables identification of performance trends, consistency evaluation, and confidence assessment in optimization results. This analysis helps distinguish real performance improvements from measurement variation or random effects.

Always conduct multiple practice flights under consistent conditions to establish baseline performance and verify optimization results. Single flight data can be misleading due to environmental variation or measurement errors.

Trimming Techniques and Procedures

Center of gravity adjustment through component repositioning or ballasting affects stability, trim, and overall flight performance. Precise CG control enables optimization of flight characteristics for specific mission requirements.

Recovery system adjustment including parachute size, streamer length, and deployment timing affects total flight time and descent rate. These adjustments must be optimized for specific events and environmental conditions.

Aerodynamic trimming through fin adjustment, surface modification, or component repositioning affects stability, drag, and overall vehicle efficiency. These adjustments require careful measurement and incremental changes to achieve optimal results.

Performance Verification and Validation

Performance verification ensures that optimization changes provide actual benefits rather than theoretical improvements. This verification requires objective measurement and comparison with baseline performance data.

Reliability validation confirms that optimized vehicles maintain acceptable levels of flight success and recovery system performance. Optimization that compromises reliability may provide no net benefit in competition.

Environmental validation tests optimized vehicles under conditions expected during actual competition. This testing ensures that performance improvements are maintained across the range of expected flight conditions.

Advanced Optimization Techniques

Advanced optimization techniques leverage modern technology and analytical methods to achieve performance levels that were previously impossible with traditional approaches. These techniques require greater investment in equipment and expertise but can provide significant competitive advantages.

Computational Analysis and Simulation

Computational fluid dynamics (CFD) analysis enables detailed prediction of aerodynamic characteristics and optimization opportunities that are difficult to identify through empirical methods alone. This analysis can guide design decisions and reduce testing requirements.

Structural analysis using finite element methods (FEM) enables optimization of component designs for minimum weight while maintaining required strength and stiffness. This analysis helps identify areas where material can be safely removed or redistributed.

Flight simulation and trajectory analysis predict vehicle performance under various conditions and help optimize design parameters for specific mission requirements. These simulations can guide trimming decisions and reduce empirical testing requirements.

Experimental and Testing Methods

Wind tunnel testing provides direct measurement of aerodynamic characteristics and validation of analytical predictions. This testing is particularly valuable for complex geometries or flow conditions that are difficult to analyze computationally.

Static testing verifies structural integrity and identifies potential failure modes before flight testing. This testing can prevent expensive flight failures and provide confidence in design optimization results.

Dynamic testing evaluates vehicle response to time-varying loads and environmental conditions that may affect flight performance. This testing can reveal issues not apparent from static analysis or steady-flight conditions.

Materials and Manufacturing Optimization

Advanced materials including carbon fiber composites, advanced polymers, and specialized alloys enable weight reduction and performance enhancement beyond traditional materials. These materials require specialized handling and processing techniques.

Precision manufacturing techniques such as computer-controlled machining, 3D printing, and advanced forming processes enable complex geometries and tight tolerances that improve performance and reduce weight. These techniques require specialized equipment and expertise.

Surface treatment and finishing optimization including advanced coatings, polishing techniques, and texture control can provide measurable drag reduction and performance enhancement. These treatments require careful application and quality control.

Optimization for Specific Event Categories

Optimization strategies must be tailored to specific event categories and competition requirements to achieve maximum competitive advantage. Different events emphasize different performance parameters and may require contradictory optimization approaches for peak performance.

Duration Event Optimization

| Optimization Focus | Techniques | Expected Benefits |

|---|---|---|

| Minimum Sink Rate | High lift-to-drag ratio design, optimal weight distribution | Extended glide phase duration |

| Recovery System Efficiency | Optimal parachute/streamer size, deployment timing | Controlled descent rate and drift |

| Structural Weight Reduction | Lightweight materials, optimized structure | Increased payload capacity for recovery systems |

Altitude Event Optimization

| Optimization Focus | Techniques | Expected Benefits |

|---|---|---|

| Maximum Thrust Efficiency | Optimal motor selection, streamlined design | Higher velocity and energy conversion |

| Minimum Drag Configuration | Smooth surfaces, minimal cross-section | Reduced energy loss to aerodynamic drag |

| Structural Efficiency | Lightweight but strong construction | Maximum energy for altitude gain |

Scale Event Optimization

| Optimization Focus | Techniques | Expected Benefits |

|---|---|---|

| Visual Accuracy | Precise dimensions, authentic details | Higher static judging scores |

| Flight Fidelity | Representative flight characteristics | Better flying scale performance |

| Weight Distribution | Balanced CG for stable flight | Authentic flight behavior |

Documentation and Replication

Thorough documentation of optimization processes and results enables precise replication of successful configurations and provides valuable reference for future development efforts. This documentation becomes increasingly important as vehicles become more complex and optimization more sophisticated.

Performance Records and Data Management

Detailed performance records including flight data, environmental conditions, and vehicle configurations enable analysis of performance trends and identification of optimization opportunities. These records should be maintained systematically for maximum value.

Configuration documentation including detailed drawings, photographs, and written descriptions ensures that successful designs can be replicated or modified for future applications. This documentation should include all relevant details that affect performance.

Process documentation including optimization procedures, testing methods, and decision rationale provides context for performance results and enables refinement of optimization approaches for future projects. This documentation helps accelerate learning and development.

Quality Control and Verification

Quality control procedures ensure that optimized vehicles maintain consistent characteristics and performance across multiple flights and construction cycles. These procedures should include inspection checkpoints and verification measurements.

Verification testing confirms that replicated vehicles maintain the performance characteristics of original optimized configurations. This testing prevents degradation of performance due to construction variations or material changes.

Continuous improvement processes use documented performance data and optimization results to refine future development efforts and accelerate achievement of performance goals. This process creates a positive feedback loop that improves capabilities over time.

Always document optimization changes and their effects, even when results are negative or inconclusive. Understanding what doesn’t work is often as valuable as knowing what does, and prevents repeated unsuccessful attempts.

Post Comment