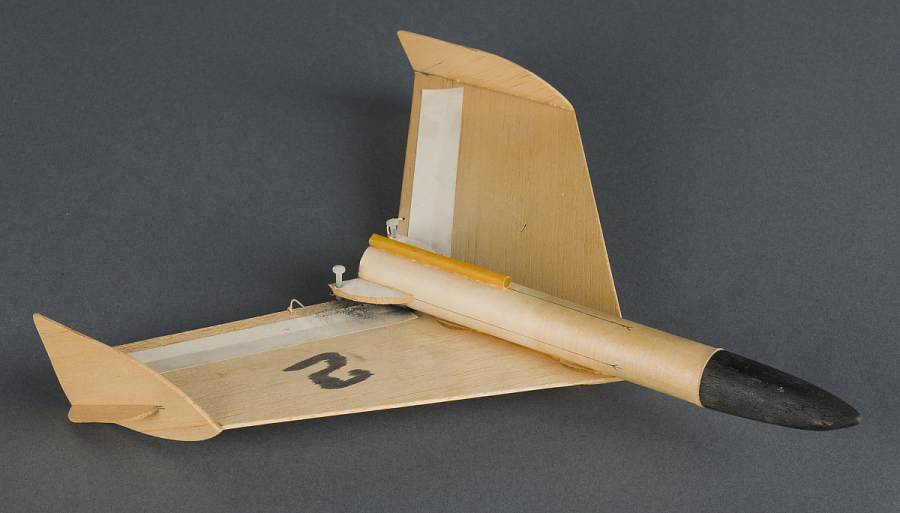

Design Variations and Performance Impact – Cast Glider L-Hooks for B Boost Glide

The design of L-hooks for B/G competition involves numerous variables that can significantly impact both performance and reliability. Understanding how different design parameters affect component behavior allows competitors to optimize their L-hooks for specific applications and flight conditions, potentially providing measurable advantages in competition.

Design optimization for L-hooks requires balancing multiple competing factors including structural strength, weight, aerodynamic characteristics, and release reliability. Each of these factors can be influenced by specific geometric features, material choices, and manufacturing techniques that must be carefully coordinated to achieve optimal results.

Modern design approaches for L-hooks incorporate both traditional engineering principles and advanced analysis techniques to achieve performance levels that were previously impossible with empirical methods alone. This evolution has enabled competitors to push the boundaries of what is achievable in B/G competition while maintaining the reliability necessary for consistent performance.

Hook Shape and Size Optimization

Hook shape and size are among the most critical design parameters for L-hooks, directly affecting both retention strength and release reliability. These parameters must be carefully optimized to ensure that the hook can withstand expected flight loads while releasing cleanly when required.

Geometric Configuration Effects

Hook curvature significantly affects both retention strength and release characteristics, with tighter curves providing greater retention force but potentially more difficult release. The optimal curvature balances these competing requirements based on specific application needs and glider design characteristics.

Hook throat dimensions determine the clearance between hook and retention pin, affecting both retention security and release smoothness. Throat dimensions must be precisely controlled to ensure adequate retention while allowing clean separation without binding or jamming.

Hook cross-sectional geometry affects both structural strength and weight, with different shapes offering specific advantages for various loading conditions. Rectangular sections provide good strength in bending, while circular sections offer uniform strength in all directions.

Use finite element analysis or empirical testing to determine optimal hook geometry for specific loading conditions. Consider both static loads during boost and dynamic loads during separation when optimizing design parameters.

Size Scaling Considerations

Hook size scaling affects both structural capacity and aerodynamic drag, with larger hooks generally providing greater strength but also increased weight and drag. The optimal size represents a compromise between these competing factors based on specific application requirements.

Scaling laws for hook strength and weight must be considered when evaluating different size options. Structural strength typically increases with the square of linear dimensions, while weight increases with the cube, creating a trade-off that favors smaller, more efficient designs.

Manufacturing constraints may limit the range of hook sizes that can be produced consistently and cost-effectively. These constraints should be considered during the design process to ensure that designs can be realized in practice.

Surface Finish and Texture Effects

Surface finish on hook contact surfaces affects both retention friction and release smoothness, with rougher surfaces typically providing greater retention force but potentially more difficult release. The optimal finish balances these competing requirements.

Texture patterns can be used to control friction characteristics in specific areas of the hook, allowing for optimization of retention and release properties independently. This approach can provide benefits not achievable with uniform surface finishes.

Coatings or surface treatments can modify hook properties without changing basic geometry, providing additional options for performance optimization. These treatments should be compatible with both casting materials and operational environments.

Weight vs. Strength Trade-offs

The fundamental trade-off between weight and strength in L-hook design directly affects glider performance and mission success. Optimizing this trade-off requires careful analysis of loading conditions and performance requirements to achieve the best possible balance for specific applications.

Material Selection Impact

Material density directly affects component weight for a given volume, making material selection one of the most important factors in weight optimization. Lower density materials can achieve equivalent strength with less weight but may have other disadvantages.

Material strength properties determine how much load can be carried for a given cross-sectional area, affecting both component size and weight. Materials with higher strength-to-weight ratios enable lighter, more compact designs.

Material cost and availability affect the practicality of different material choices, particularly for competitors with limited budgets or access to specialized materials. These factors must be balanced against performance benefits.

| Material | Density (g/cm³) | Yield Strength (MPa) | Strength-to-Weight Ratio |

|---|---|---|---|

| Zamak 3 | 6.6 | 250 | 37.9 |

| Aluminum 380 | 2.7 | 200 | 74.1 |

| Titanium Grade 5 | 4.4 | 880 | 200.0 |

| Stainless Steel 304 | 8.0 | 205 | 25.6 |

Geometric Optimization Techniques

Hollow section design can significantly reduce weight while maintaining structural stiffness, particularly for components with primarily bending loads. This approach requires careful analysis to ensure adequate wall thickness for strength and manufacturing constraints.

Variable cross-section design allows for optimization of material distribution based on load requirements, placing material where it is most needed while minimizing weight in low-stress areas. This approach can provide significant weight savings for complex loading conditions.

Topology optimization techniques can identify optimal material distribution for specific loading conditions, enabling designs that minimize weight while maintaining required strength and stiffness. These techniques require advanced analysis tools but can provide significant performance improvements.

Performance Impact Assessment

Weight reduction in L-hooks directly affects glider payload capacity, enabling increased performance features or extended flight times. Even small weight savings can provide measurable advantages in competition.

Strength optimization ensures reliable performance under expected loading conditions while avoiding unnecessary conservatism that adds weight without benefit. This optimization requires accurate load analysis and appropriate safety factors.

Fatigue resistance affects long-term reliability and must be considered when optimizing weight and strength trade-offs. Components that fail due to fatigue can compromise entire missions regardless of static strength adequacy.

Aerodynamic Considerations

While L-hooks are relatively small components, their aerodynamic characteristics can significantly affect overall vehicle performance, particularly during the critical boost phase when every increment of drag reduction can improve separation velocity and altitude.

Drag Minimization Strategies

Streamlined hook profiles can reduce drag compared to blunt or angular shapes, particularly at higher speeds where pressure drag becomes significant. These profiles should be optimized for expected flight conditions while maintaining functional requirements.

Surface smoothness and finish quality significantly affect skin friction drag, with smoother surfaces generally providing lower drag coefficients. Proper finishing techniques including polishing and coating can provide meaningful drag reduction.

Component placement on the glider affects local flow conditions and overall drag contribution. Hooks placed in regions of favorable pressure gradients or attached flow can experience significantly lower drag than those in separated flow regions.

Even small reductions in L-hook drag can provide measurable improvements in separation velocity and altitude, particularly with high-thrust B-class motors. Every gram of saved propellant energy translates directly into improved mission performance.

Flow Interaction Effects

L-hook interaction with glider flow field can create localized separation or increased drag that affects overall vehicle performance. These interactions should be considered when optimizing hook placement and orientation.

Wake effects from L-hooks can interfere with glider control surfaces or recovery systems, potentially affecting stability or deployment reliability. These effects should be evaluated during design and testing.

Pressure distribution around L-hooks affects both drag and potential for flow-induced vibration or resonance. Components that experience significant pressure fluctuations may require additional damping or structural reinforcement.

Computational Analysis Methods

Computational fluid dynamics (CFD) analysis can predict aerodynamic characteristics of L-hook designs and identify opportunities for drag reduction. This analysis is particularly valuable for complex geometries or flow conditions.

Wind tunnel testing provides direct measurement of aerodynamic characteristics and can validate analytical predictions. This testing is especially valuable for verifying drag reduction claims and optimizing designs for specific conditions.

Empirical testing in actual flight conditions provides the most realistic evaluation of aerodynamic performance but requires careful instrumentation and data collection to isolate hook effects from other variables.

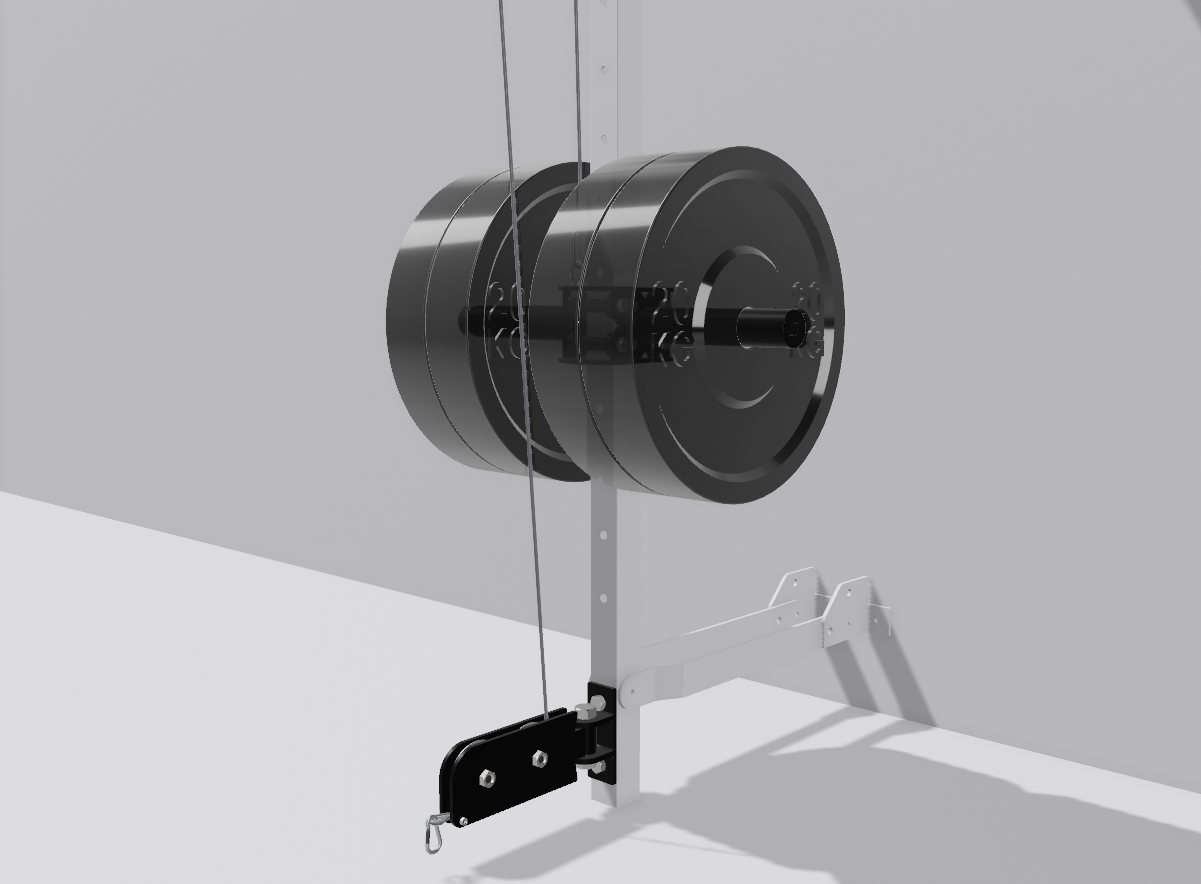

Release Mechanism Integration

Successful L-hook design requires careful integration with glider release mechanisms to ensure reliable separation and predictable flight behavior. This integration affects both the hook design itself and its interaction with other glider components.

Retention Pin Compatibility

Hook geometry must be compatible with retention pin diameter and shape to ensure adequate retention force and clean release. Mismatched components can cause binding, incomplete release, or premature separation.

Surface treatments on retention pins can affect friction characteristics and release behavior, requiring coordination with hook design and materials. These treatments should be compatible with both hook materials and operational environments.

Pin actuation mechanisms affect release timing and reliability, requiring hooks that can withstand the forces generated during actuation while providing predictable release behavior. This requirement affects both hook strength and geometry.

Dynamic Release Behavior

Release dynamics affect glider flight initiation and must be optimized to ensure stable transition from powered to unpowered flight. Hooks that release too abruptly can impart destabilizing forces, while those that release too slowly can reduce separation velocity.

Separation impulse affects initial glider velocity and attitude, requiring hooks that provide appropriate release characteristics for specific glider designs. This requirement affects hook mass distribution and release mechanism design.

Timing coordination between hook release and motor burnout affects overall flight profile and must be optimized for maximum performance. Hooks that release too early waste potential altitude, while those that release too late risk motor case damage.

Interface Load Management

Load transfer between hook and glider structure affects both component integrity and overall vehicle performance. Hooks must be designed to distribute loads effectively while minimizing stress concentrations.

Attachment point design affects load path efficiency and structural weight, requiring optimization for specific loading conditions and glider configurations. These points should be located to minimize bending moments and maximize structural efficiency.

Vibration and shock loading during release can create transient loads that significantly exceed static load estimates. Hooks must be designed to withstand these dynamic loads while maintaining release reliability.

Design Validation and Testing

Validation of L-hook design variations requires systematic testing to verify performance predictions and identify potential issues before competition use. This validation ensures that design changes provide actual benefits rather than theoretical improvements.

Static Load Testing

Static load testing verifies that hooks can withstand expected flight loads without failure or excessive deformation. This testing should simulate actual loading conditions as closely as possible while maintaining safety.

Load application methods affect test accuracy and should be designed to simulate actual loading conditions. Improper load application can create stress concentrations or loading patterns that do not represent actual flight conditions.

Test instrumentation enables measurement of critical parameters such as load, displacement, and strain during testing. This instrumentation provides data necessary for design validation and performance assessment.

Dynamic Performance Testing

Dynamic testing evaluates hook performance under time-varying loads such as those experienced during motor ignition or separation events. This testing can reveal issues not apparent from static analysis.

Impact testing simulates separation events and evaluates hook behavior under transient loading conditions. This testing is particularly important for verifying release reliability and separation characteristics.

Fatigue testing evaluates hook performance under repeated loading cycles, which is critical for competitors who use the same hooks for multiple flights. This testing can identify potential failure points before actual use.

Always conduct testing with appropriate safety precautions including protective equipment, barriers, and remote activation where possible. Ensure that test fixtures are adequately strong and that failure modes are contained safely.

Post Comment